How to print on lanyards

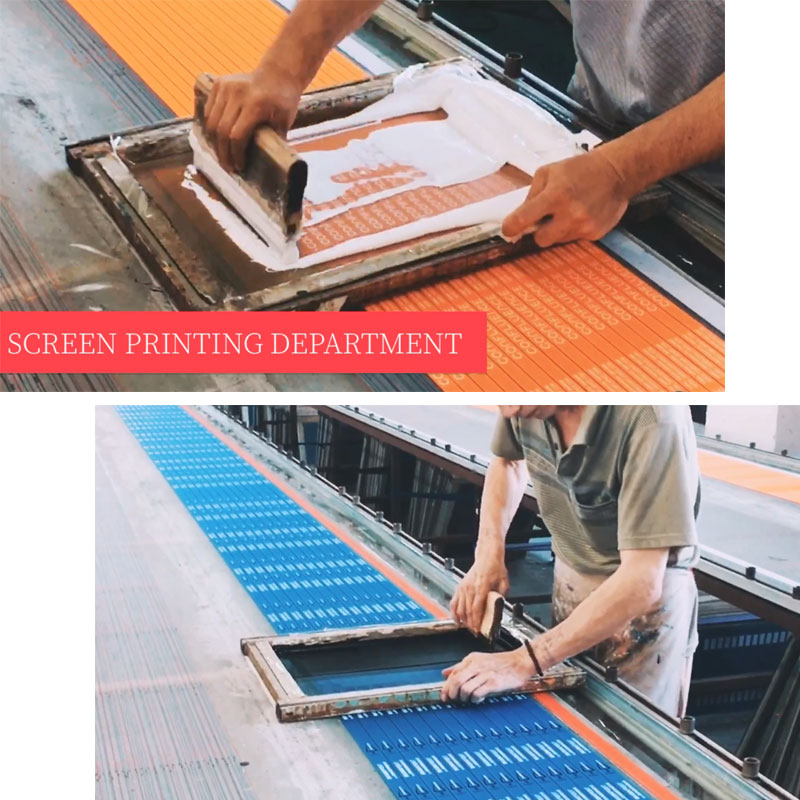

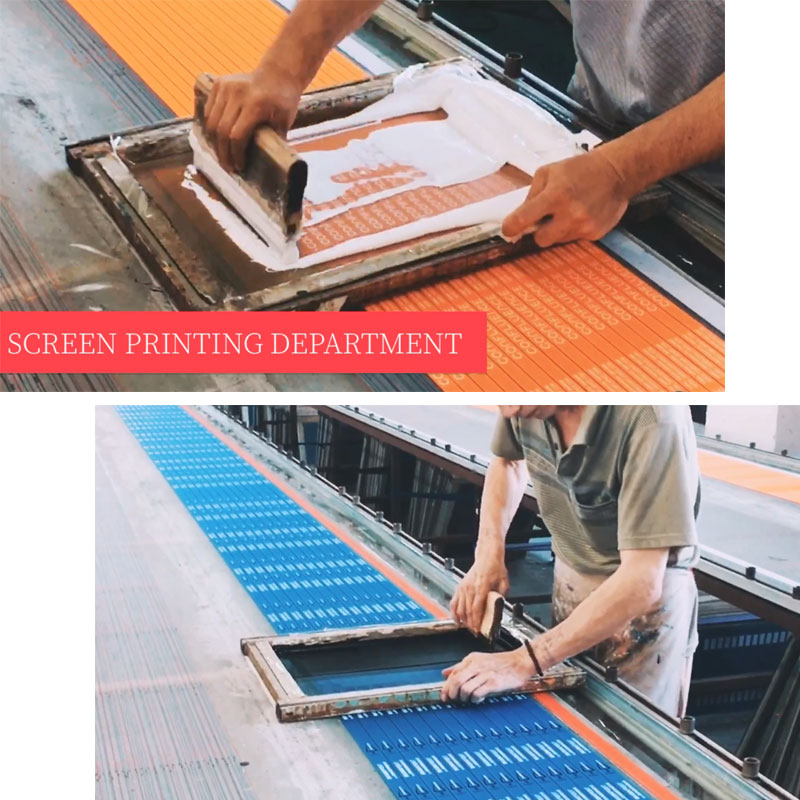

Screen printing or silk screening is a printing technique particularly suited for flat or relatively flat surfaces. How to print on lanyards?The heart of the process involves a fine mesh or screen that is tightly stretched around a rigid frame. The areas that are not to be printed are masked out on the screen, and to create the print, the framed screen is positioned over the item to be printed, along with a dollop of thick ink. A squeegee is then used to press the ink through the screen.

The masked areas prevent ink from passing through, but the unmasked areas allow the ink to be imprinted on the material. The item is then sent on a conveyor belt through a heat-tunnel. This curing process ensures that the inks dry quickly so that they materials can be stacked or packaged. Properly cured inks will remain on the printed substrate even under harsh conditions.

How to print on lanyards?If more colors are desired in the final design, the process is repeated with different screens. A design that requires four different colors would, therefore, require four different screens. The screens are usually placed on a rotary press that allows the different color prints to be properly aligned or registered with each other. Some screen-printers have fully automatic presses that do not require any manual labor other than set-up and loading/unloading.

About lanyard

Welcome to gcwebbing.com, we are one of the first class lanyard manufacturing companies in China. Honestly, you need is lanyard, we have! Why are you on our website? There are a few companies to provide customized products of blue print, why are we? We are competitive in price, but we also provide the speed, quality and world-class customer service. Our enthusiastic sales staff will do everything possible to provide you with five star customer service and provide the best service for you. Look forward to your visist.

About silk screening

There are several ways to screen the screen. The most direct method is to use the mask directly on the screen. This technique is suitable for simple or two color graphics, but is invalid for more complex printing. For multi-color work, screen printers often use light-sensitive emulsions. First, the design is done on a transparent plastic film. The photosensitive coating is applied to the entire screen surface and then dries. The film is placed on the ready screen, and they are exposed to bright light. After a while, the exposed areas can be washed off the screen so the screen can be printed.

Silk screen printing is most commonly used in t-shirts, garments and other fabrics, but is also used in various other materials, from plastics to metals. Although small and complex details can be captured, this technique is ideal for bold and peaceful design.