how to make lanyards?

Guanchang is the promotional products factory in China, main products including id card holder lanyard , polyester lanyard, tubular lanyard, sublimation lanyard, screen printing lanyard, medal ribbon, luggage strap, dog leash and collar , shoelaces,etc. So you get the professional answer for about the how to make lanyards.

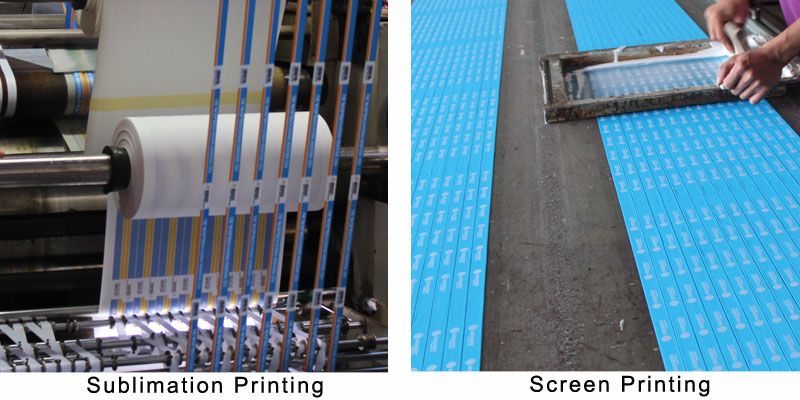

As much as we like to think of a lanyard being such a simple product the process behind it is fairly complex. First we need woven the yarn into straps by the machines that operate at very high speed, next step is printing the logo on the straps.

We common logo technology include sublimation printing , screen printing and woven logo into strap,etc. The most important component of the production line is the printer. The method employed by the manufacturers in printing their lanyards is usually screen printing. Compared to the other two most commonly used methods of Dye Sublimation and Woven logo, this method provides good quality at a reasonable price. Woven logo is the most expensive, Colorful lanyard usually through Dye Sublimation printing and it’s the best choice for large order. Screen Printing also very durable and also heat treated so you get high-resolution artwork. Nylon and cotton are the most preferred materials for this type of printing because they are smoother and allow more details to be imprinted. Typically, the screen printed lanyards are printed in one or two colors. Although single-sided printed is more cost effective and most common, some customers prefer double sided printing as well.

Hot cut the printed straps as we need.

Sewing the accessories on the straps.